ABOUT US

WHAT SEPARATES US FROM THE REST

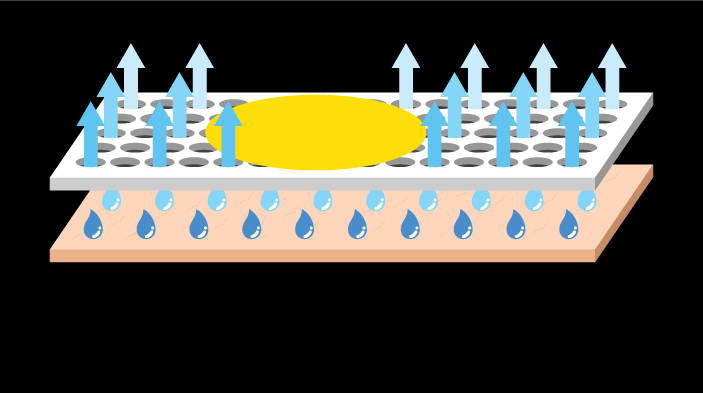

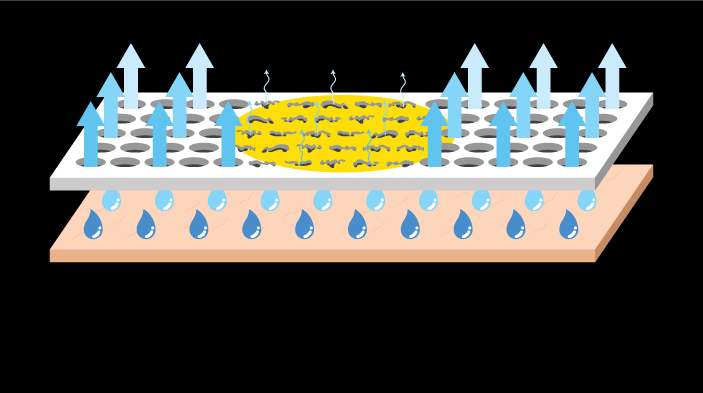

With the introduction of polyester performance fabrics into the market place decorators were challenged with attempting to secure a soft hand and to stop dye migration from the shirt into the design. There were two primary ways to apply a preprint onto a polyester tees. Printers used traditional plastisol inks, however, the hand was poor and they experienced dye migration on occasion. The other option was dye sublimation. Dye sublimation required a design to be printed on paper and then applied thru heat and pressure onto the garment. This process left a platen mark on the tee due to the heat and pressure.

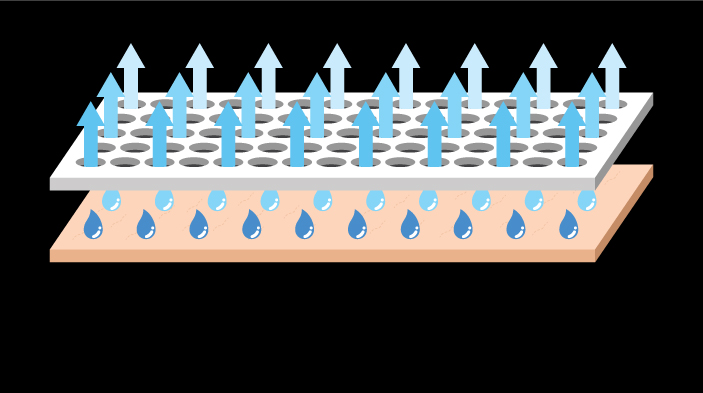

Traditional printing will close off the polyester capillary fiber from wicking moisture while dye sublimation will reduce the performance of the shirt from 40% to 60% and in some cases can completely destroy the moisture wicking property if the heat is applied for to long or at too high a temperature.

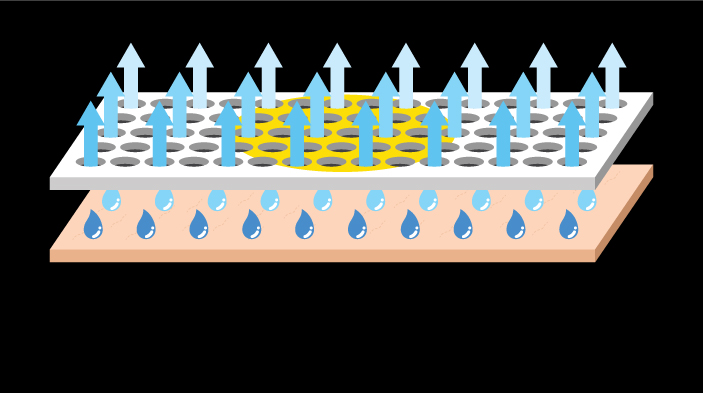

PolyHD was invented to solve both of these problems. PolyHD is applied with traditional silk screen equipment therefore using no excess heat and no pressure. The process uses traditional dyes to achieve the best results. By dyeing the fiber there is absolutely no hand and the moisture wicking properties are not interfered with. The end result gives you the only true performance shirt on the market that is decorated with a preprint.

Click through our infographics below